Introduction

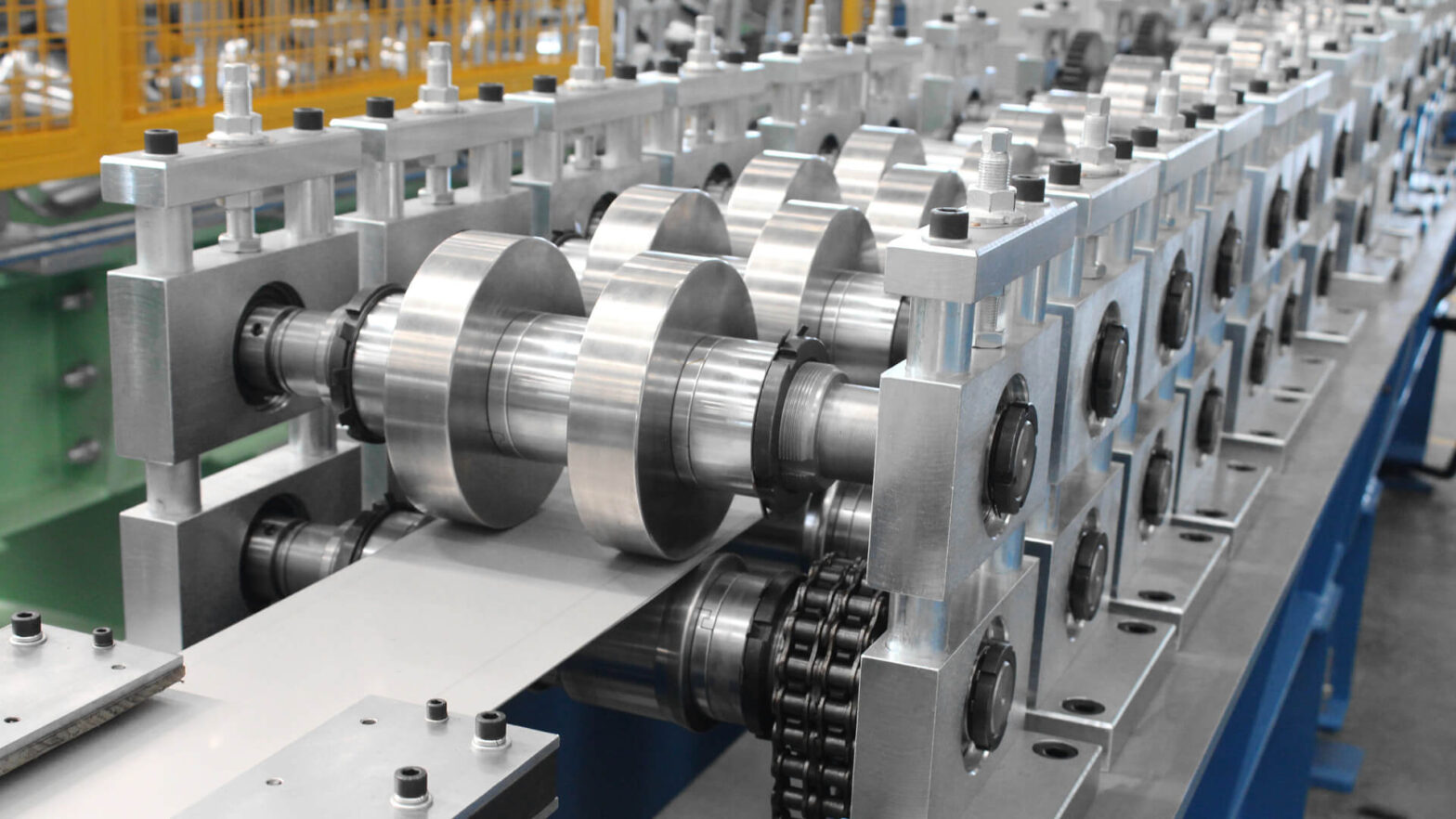

Steel roll forming is a process used to fabricate steel shapes and components for a variety of industries. It involves rolling a flat steel strip through a series of rollers, which progressively shape the strip into the desired shape. The steel roll forming industry uses a variety of steel grades and types to produce components for a variety of applications. In this blog, we will discuss the different types of steel that the steel roll forming industry uses, their properties, and the advantages they offer.

What Steel Does the Steel Roll Forming Industry Use?

The steel roll forming industry uses a variety of steel grades and types to produce components for a variety of applications. These include:

Cold Rolled Steel: Cold rolled steel is a type of steel that is produced by cold rolling a steel strip through a series of rollers. The process of cold rolling increases the strength and hardness of the steel, making it ideal for applications that require strength and durability. Cold rolled steel is commonly used in the steel roll forming industry to form shapes and components that require strength and durability.

Hot Rolled Steel: Hot rolled steel is produced by heating a steel strip above its recrystallization temperature and then rolling it through a series of rollers. The process of hot rolling increases the strength and hardness of the steel, making it ideal for applications that require strength and durability. Hot rolled steel is often used in the steel roll forming industry for components that require strength and durability.

Galvanized Steel: Galvanized steel is a type of steel that is coated with a layer of zinc for corrosion protection. The process of galvanizing increases the corrosion resistance of the steel, making it ideal for applications that require corrosion protection. Galvanized steel is often used in the steel roll forming industry for components that require corrosion protection.

Aluminized Steel: Aluminized steel is a type of steel that is coated with a layer of aluminum for corrosion protection. The process of aluminizing increases the corrosion resistance of the steel, making it ideal for applications that require corrosion protection. Aluminized steel is often used in the steel roll forming industry for components that require corrosion protection.

Stainless Steel: Stainless steel is a type of steel that is resistant to corrosion and oxidation. The process of stainless steel production increases the corrosion and oxidation resistance of the steel, making it ideal for applications that require corrosion and oxidation resistance. Stainless steel is often used in the steel roll forming industry for components that require corrosion and oxidation resistance.

What Are the Properties and Advantages of Steel Roll Formed Steel?

The steel roll forming industry uses a variety of steel grades and types to produce components for a variety of applications. Each type of steel offers its own unique properties and advantages.

Cold Rolled Steel: Cold rolled steel offers excellent strength and hardness, making it ideal for applications that require strength and durability. Cold rolled steel is also easy to form and can be cold formed into complex shapes.

Hot Rolled Steel: Hot rolled steel offers excellent strength and hardness, making it ideal for applications that require strength and durability. Hot rolled steel is also easy to form and can be hot formed into complex shapes.

Galvanized Steel: Galvanized steel offers excellent corrosion resistance, making it ideal for applications that require corrosion protection. Galvanized steel is also easy to form and can be formed into complex shapes.

Aluminized Steel: Aluminized steel offers excellent corrosion resistance, making it ideal for applications that require corrosion protection. Aluminized steel is also easy to form and can be formed into complex shapes.

Stainless Steel: Stainless steel offers excellent corrosion and oxidation resistance, making it ideal for applications that require corrosion and oxidation resistance. Stainless steel is also easy to form and can be formed into complex shapes.

Conclusion

Steel roll forming is a process used to fabricate steel shapes and components for a variety of industries. The steel roll forming industry uses a variety of steel grades and types to produce components for a variety of applications. These include cold rolled steel, hot rolled steel, galvanized steel, aluminized steel, and stainless steel. Each type of steel offers its own unique properties and advantages. Cold rolled steel offers excellent strength and hardness, hot rolled steel offers excellent strength and hardness, galvanized steel offers excellent corrosion resistance, aluminized steel offers excellent corrosion resistance, and stainless steel offers excellent corrosion and oxidation resistance.

By understanding the different types of steel that the steel roll forming industry uses, their properties, and their advantages, you can ensure that you are choosing the right steel for your application.