Not all steel is made equally. Steel comes in a variety of forms, such as carbon steel, steel alloys, and stainless steel. Each of these has usefulness in several applications, and each application determines how highly it is regarded. Depending on how the steel will be utilised, two distinct (and entirely independent) organisations are responsible for grading it.

Similarly, you will notice two different steel grade formats. The first is from ASTM International, which utilises a letter designation based on the type of steel followed by numbers denoting the steel’s properties to grade steel for use in building. The second comes from SAE International, a company that grades steel for use in the aerospace and automobile industries.

It’s crucial to keep in mind that these steel varieties have additional uses. Both of these grading schemes produce the two most used steel kinds.

Steel for construction ASTM A53

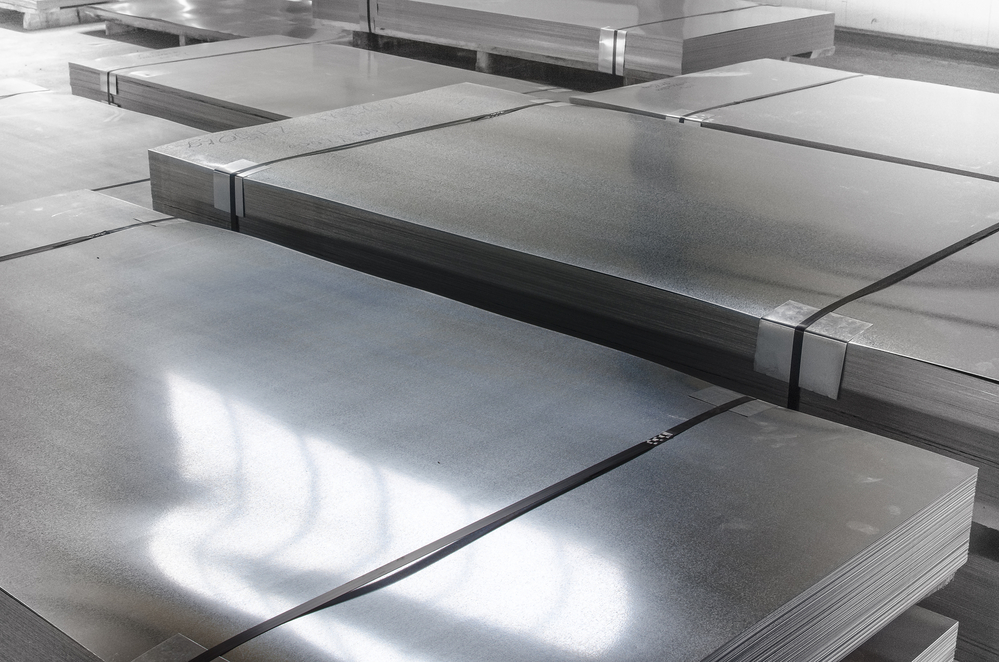

The most often used grade of carbon steel is ASTM A53, which is utilised for low-pressure pipes and structural building. Do not be misled by the grade; several types of steel can even be found in the same grade. Hot-dipped galvanised steel and seamless and welded black steel are both covered by the ASTM A53 standard. There are three types—F, E, and S—and two grades (A/B) available.

Different applications call for different types. Furnace-related piping is made of type F. While Type S is seamless pipe, Type E has electrical resistance. The most popular form of carbon steel pipes we provide, Grade B seamless, has numerous applications in residential, commercial, and industrial settings.

The SAE stainless steel grading system

In addition to stainless steel, SAE also grades steel for usage in the automobile and aerospace industries. Of course, stainless steel has a lot of uses in mechanics. It is simple to understand why stainless steel frequently “steels” the show given its versatility and suitability for hygienic surroundings.

Four-digit numbers are used to identify SAE steel grades. The grade of steel is indicated by the first numeral. The concentration of the alloying ingredient is indicated by the second digit. The concentration of carbon in the steel is indicated by the last two digits of the grade.

The 304 stainless steel grade is the most widely used among SAE steels. Nickel and chromium are both used as alloying ingredients in this steel. Because SAE 304 stainless steel is austenitic, it is less thermally and electrically conductive than carbon steel. Although it gives a stronger corrosion resistance in commerce, it is also less magnetic. Stainless steel may be easily moulded into any technical or mechanical parts required, making it a very versatile material.

As you can see, there are various applications for both of these steel types. Although these are the products that are most frequently bought from us, we also have others that might be more suited to your needs. You can get assistance from our specialists in choosing the best approach for your project.