In today’s dynamic economic landscape, the steel industry faces constant evolution and adaptation. Rapid changes in market conditions, technological advancements, and global trends necessitate proactive strategies for businesses to thrive. This blog explores effective approaches and strategies for steel companies to adapt swiftly to these changes.

In today’s dynamic economic landscape, the steel industry faces constant evolution and adaptation. Rapid changes in market conditions, technological advancements, and global trends necessitate proactive strategies for businesses to thrive. This blog explores effective approaches and strategies for steel companies to adapt swiftly to these changes.

Key Factors Driving Rapid Changes

- Technological Innovation: Advanced technologies, including artificial intelligence (AI) and the Internet of Things (IoT), are revolutionizing steel production and operational efficiencies.

- Regulatory Shifts: Changing environmental regulations and policies impact production processes and operational costs.

- Global Demand Fluctuations: Variations in global demand, influenced by geopolitical events and economic conditions, necessitate agile responses from steel companies.

Strategies for Adapting to Rapid Changes

Investing in Technology and Innovation

The role of advanced analytics, AI, and IoT in optimizing operations and decision-making is crucial. The following table showcases the impact of AI on reducing production costs and enhancing efficiency:

| AI Application | Cost Reduction (%) | Efficiency Improvement (%) |

|---|---|---|

| Predictive Maintenance | 15-20 | 25-30 |

| Smart Inventory Management | 10-15 | 20-25 |

Agility in Supply Chain Management

Agile supply chains are essential for responding quickly to market fluctuations. Instead of a graph, consider data on how flexible supply chains outperform traditional ones during market shifts.

Diversification of Product Offerings

Diversifying product portfolios helps mitigate risks and cater to varying market demands. This strategy is demonstrated through successful case studies in the industry.

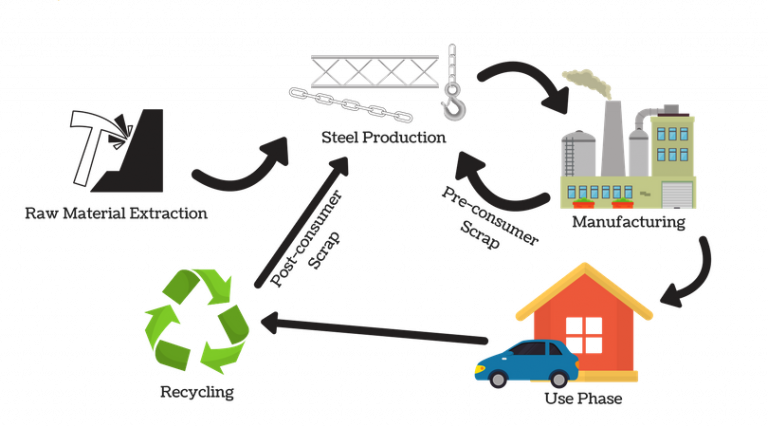

Adopting Sustainable Practices

Sustainability is increasingly important in the steel industry. Companies adopting sustainable practices see positive impacts on consumer preference and market share.