- Emphasize the importance of quality in steel production for durability, safety, and market competitiveness.

- Overview of key best practices for maintaining high-quality output.

Quality Standards in Steel Production

- Relevant Standards: ASTM, ISO, and other industry standards.

- Importance: Adherence ensures product reliability and meets customer specifications.

3. Best Practices for Quality Assurance

-

Raw Material Inspection

- Conduct thorough checks to verify material composition, purity, and integrity.

- Use advanced spectroscopy and imaging technologies for precise analysis.

Table: Raw Material Inspection Criteria

Criterion Description Material Composition Verify elements and alloys present Purity Check for contaminants Integrity Assess structural soundness -

Process Control Measures

- Monitor production parameters such as temperature and pressure.

- Implement real-time adjustments to optimize manufacturing conditions.

-

Testing Protocols

- Use non-destructive testing methods like ultrasonic testing and magnetic particle inspection to detect defects.

Graph: Comparison of Non-Destructive Testing Methods

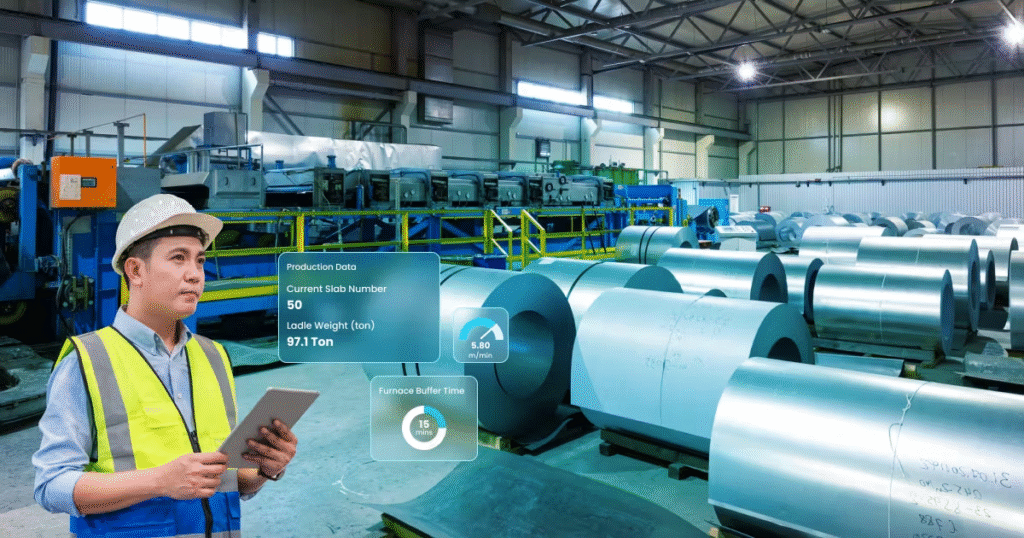

Technological Innovations

- AI-Driven Quality Control

- Real-time analysis of production data to identify defects and anomalies.

- IoT Applications

- Sensors monitor equipment performance and environmental conditions to enhance process reliability