Steel cutting and forming are critical processes in the steel industry, directly impacting production efficiency, product quality, and operational costs. As the industry faces increasing pressure to enhance productivity while maintaining high standards, innovations in these processes are crucial. This blog explores the latest advancements in steel cutting and forming technologies that are revolutionizing efficiency in the steel sector.

Innovations in Steel Cutting

-

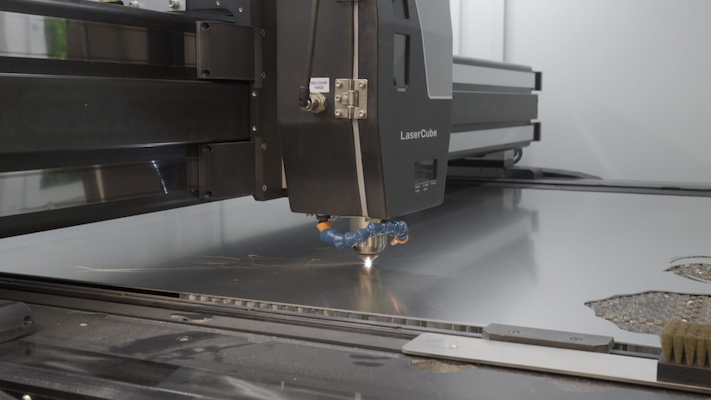

Laser Cutting Technology

- Overview: Laser cutting uses a high-powered laser beam to cut through steel with precision. It offers superior accuracy compared to traditional methods.

- Benefits:

- Precision: Achieves intricate cuts with minimal tolerances.

- Speed: Faster than conventional cutting methods.

- Reduced Waste: Minimizes material waste due to accurate cutting.

- Applications: Ideal for applications requiring detailed designs and tight tolerances.

-

Plasma Cutting

- Overview: Plasma cutting utilizes a plasma torch to cut through steel. The high-temperature plasma stream melts the steel and blows away the molten material.

- Benefits:

- Versatility: Suitable for various steel thicknesses.

- Speed: Cuts steel quickly with minimal post-processing.

- Cost-Effective: Generally less expensive than laser cutting for thicker materials.

- Applications: Effective for cutting thick steel plates and for applications where speed is crucial.

-

Waterjet Cutting

- Overview: Waterjet cutting employs a high-pressure stream of water mixed with abrasive materials to cut through steel.

- Benefits:

- No Heat Affected Zone: Reduces thermal distortion in the steel.

- Complex Shapes: Capable of cutting complex shapes and contours.

- Minimal Waste: High precision reduces material waste.

- Applications: Suitable for cutting complex shapes and thick steel without affecting the material properties.

Innovations in Steel Forming

-

Advanced Roll Forming

- Overview: Roll forming involves passing steel through a series of rollers to achieve desired shapes and profiles.

- Benefits:

- Consistency: Produces uniform cross-sections with high precision.

- High Speed: Enables continuous production of long steel sections.

- Reduced Waste: Efficient use of material with minimal scrap.

- Applications: Used for manufacturing structural components, automotive parts, and building materials.

-

Hydraulic Press Forming

- Overview: Hydraulic presses use high-pressure hydraulic fluid to shape steel sheets into complex forms.

- Benefits:

- High Force: Capable of forming thick and hard steel materials.

- Flexibility: Allows for the production of various shapes and sizes.

- Precision: Achieves detailed and intricate forms with high accuracy.

- Applications: Ideal for producing custom and complex components, including automotive and aerospace parts.

-

Superplastic Forming

- Overview: This technique involves heating steel to a temperature where it becomes superplastic and can be shaped into complex geometries under low pressure.

- Benefits:

- Complex Shapes: Enables the production of intricate designs.

- Reduced Tooling Costs: Lower costs compared to traditional forming methods for complex shapes.

- High Strength: Produces parts with enhanced mechanical properties.

- Applications: Used in aerospace, automotive, and advanced manufacturing sectors for parts requiring high precision and strength.