Introduction

Steel is one of the most commonly used materials in the construction and manufacturing industry. It is strong, durable and versatile, making it an ideal choice for a variety of applications. But, how is steel made? This blog will answer this question and explore the steps and processes involved in producing steel from raw materials. We will look at the different types of steel, the raw materials used, the different processes involved and the importance of quality control. We will also explore the environmental impacts of steel production and discuss how steel is being used in the modern world.

What is Steel?

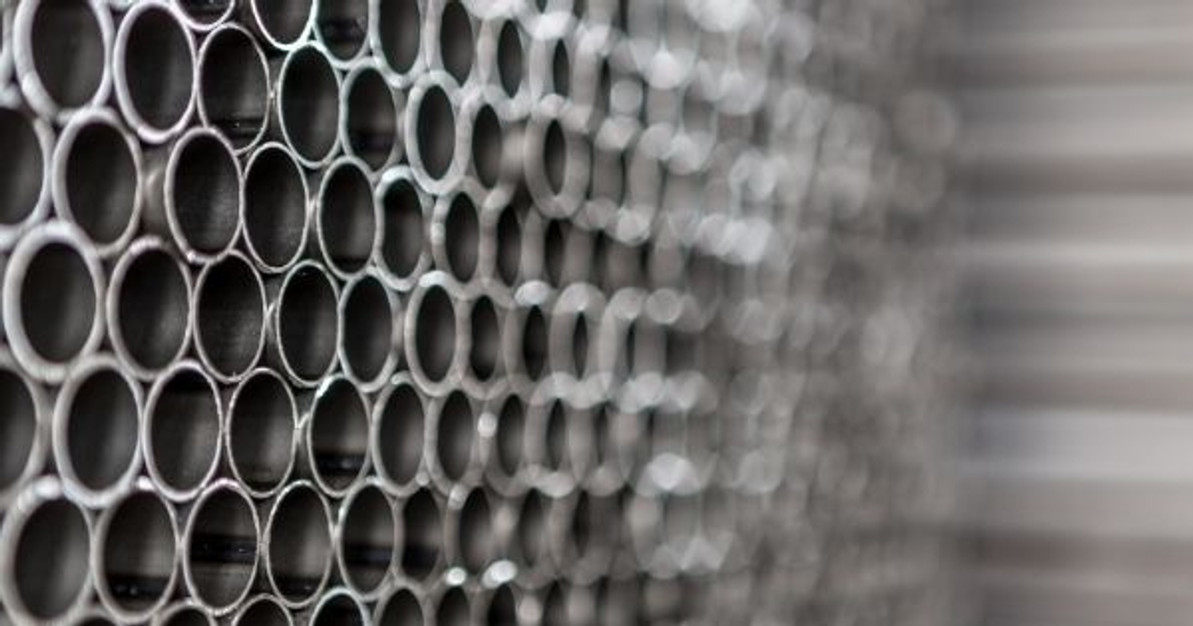

Steel is an alloy made up of iron and other elements, such as carbon, manganese, chromium, tungsten and vanadium. It is an extremely strong and durable material, with a variety of uses in the construction and manufacturing industry. Steel has a high tensile strength, making it an ideal choice for applications that require strength and durability, such as buildings, bridges, cars and ships.

Types of Steel

There are a variety of different types of steel, each with its own unique properties. The most common types of steel include mild steel, stainless steel, tool steel and alloy steel. Mild steel is the most widely used type of steel, due to its low cost and versatility. It is used in a variety of applications, such as construction, automotive and industrial. Stainless steel is a type of alloy steel that is highly corrosion-resistant, making it ideal for applications that require resistance to rust and corrosion, such as kitchen appliances. Tool steel is a type of alloy steel that is incredibly hard, making it ideal for cutting and machining applications. Alloy steel is a type of steel that contains a variety of different elements, such as chromium, manganese, tungsten and vanadium. It is often used in applications that require high strength, such as automotive and aerospace.

Raw Materials Used in Steel Production

Steel is produced from a variety of different raw materials, including iron ore, coal and limestone. Iron ore is the most commonly used raw material in steel production, as it is the primary source of iron, which is essential for steel production. It is typically found in the form of hematite or magnetite and is usually mined from the ground. Coal is used as a source of energy during the steel production process, as it is needed to heat and melt the raw materials. Limestone is used as a flux, which helps to remove impurities from the raw materials, such as sulfur and phosphorus.

Processes Involved in Steel Production

The production of steel is a complex process that involves a variety of different steps and processes. The first step is the preparation of the raw materials, which involves crushing the iron ore, coal and limestone into small pieces. The next step is the smelting process, which involves heating the raw materials in a furnace to a high temperature. This process helps to melt the raw materials and remove impurities, such as sulfur and phosphorus. The molten material is then poured into a steel-making vessel, where it is further heated and stirred. This process helps to form the steel into its final shape and give it its desired properties.

The next step is the casting process, which involves pouring the molten steel into molds to form the desired shape. Finally, the steel is cooled and the finished product is ready for use.

Importance of Quality Control

Quality control is an essential part of the steel production process, as it ensures that the final product meets the desired specifications. Quality control involves a variety of steps, such as testing the raw materials for impurities, testing the molten steel for composition and temperature, and inspecting the final product for any defects. Quality control is a critical part of steel production, as it helps to ensure that the finished product is safe, reliable and of the highest quality.

Environmental Impacts of Steel Production

Steel production can have a significant impact on the environment, due to the energy and resources required to produce it. The production of steel uses significant amounts of energy, which can result in air pollution and the emission of greenhouse gases. The mining of iron ore can also result in significant environmental damage, as it often requires the clearing of land and the disruption of habitats. To mitigate these impacts, steel producers have implemented a variety of measures, such as reducing energy consumption and using recycled materials.

Conclusion

Steel is an essential material in the construction and manufacturing industry, due to its strength, durability and versatility. But, how is steel made? This blog has explored the steps and processes involved in producing steel from raw materials, such as iron ore, coal and limestone. We have also looked at the different types of steel, the importance of quality control and the environmental impacts of steel production. Steel is an incredibly versatile material, with a variety of uses in the modern world.