In the dynamic landscape of global supply chains, disruptions are inevitable. Whether caused by natural disasters, geopolitical shifts, or unexpected demand fluctuations, these disruptions can severely impact businesses across industries. For companies in the steel and metals sector, where supply chain efficiency is critical, navigating these challenges requires foresight, resilience, and strategic planning. This blog explores ten effective strategies to mitigate and manage supply chain disruptions effectively.

- Diversify Supplier Base One of the most proactive steps a company can take is to diversify its supplier base. Relying on multiple suppliers for critical materials or components reduces dependence on a single source. This strategy spreads risk and ensures continuity of supply even if one supplier faces disruptions.

| Strategy | Description |

|---|---|

| Diversify Supplier Base | Reduce reliance on single suppliers by engaging multiple sources. |

- Strengthen Supplier Relationships Building strong relationships with suppliers goes beyond transactional interactions. It involves open communication, mutual trust, and collaboration. Strong relationships often mean suppliers are more likely to prioritize your orders during shortages or allocate resources during disruptions.

| Strategy | Description |

|---|---|

| Strengthen Supplier Relationships | Foster trust and collaboration with suppliers to enhance responsiveness during disruptions. |

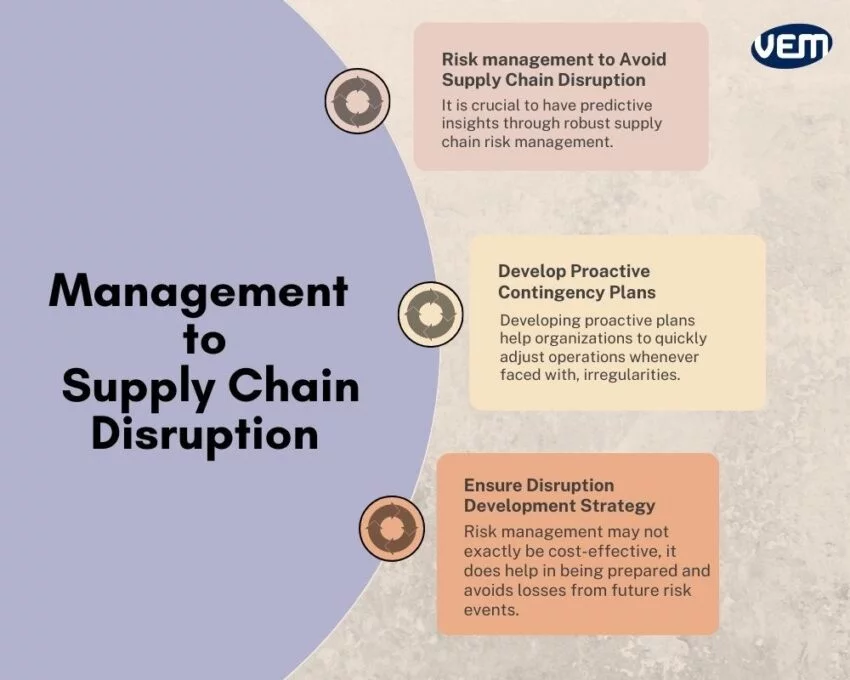

- Implement Robust Risk Management Strategies Developing and implementing robust risk management strategies is crucial. This involves identifying potential risks, assessing their impact, and developing contingency plans. Scenario planning and simulations can help prepare for various disruption scenarios.

| Strategy | Description |

|---|---|

| Implement Risk Management Strategies | Identify risks, assess impact, and develop contingency plans through scenario planning. |

- Utilize Technology for Real-Time Tracking Leveraging technology such as IoT (Internet of Things) devices and advanced analytics enables real-time tracking of inventory and shipments. This visibility into the supply chain helps identify disruptions early, allowing for timely interventions.

| Strategy | Description |

|---|---|

| Utilize Technology for Tracking | Employ IoT and analytics for real-time monitoring of inventory and shipments. |

- Maintain Buffer Stock Buffer stock or safety stock acts as a cushion against sudden demand spikes or supply disruptions. While maintaining excess inventory can increase costs, strategically placing buffer stock at critical points in the supply chain can minimize disruptions.

| Strategy | Description |

|---|---|

| Maintain Buffer Stock | Keep reserve inventory to mitigate the impact of sudden disruptions or demand fluctuations. |

- Diversify Transportation Modes Relying on a single mode of transportation exposes businesses to risks associated with that mode (e.g., strikes, weather disruptions). Diversifying transportation options—such as using both rail and road—provides flexibility and alternative routes during disruptions.

| Strategy | Description |

|---|---|

| Diversify Transportation Modes | Use multiple transportation modes to mitigate risks associated with a single mode. |

- Develop Clear Communication Channels Effective communication is critical during supply chain disruptions. Establishing clear communication channels with suppliers, logistics partners, and internal teams ensures everyone is informed promptly. This transparency facilitates quicker decision-making and response.

| Strategy | Description |

|---|---|

| Develop Clear Communication Channels | Establish transparent communication channels with stakeholders for swift response during disruptions. |

- Engage in Continuous Monitoring and Adaptation Supply chain dynamics evolve constantly. Engaging in continuous monitoring of market conditions, supplier performance, and geopolitical factors helps anticipate disruptions. Being adaptable allows companies to adjust strategies proactively.

| Strategy | Description |

|---|---|

| Continuous Monitoring and Adaptation | Stay updated on market changes and adapt supply chain strategies proactively. |

- Invest in Employee Training and Cross-Training Employee expertise and flexibility are invaluable during disruptions. Investing in training programs and cross-training employees across different roles within the supply chain enhances resilience. This versatility ensures operations can continue smoothly despite disruptions.

| Strategy | Description |

|---|---|

| Invest in Employee Training | Train employees across roles to ensure operational continuity during disruptions. |

- Collaborate with Industry Peers Collaboration with industry peers through alliances or consortiums can strengthen supply chain resilience. Sharing best practices, resources, and information about potential disruptions enhances collective preparedness and response capabilities.

| Strategy | Description |

|---|---|

| Collaborate with Industry Peers | Form alliances with peers to share resources and best practices for enhanced resilience. |

Navigating supply chain disruptions requires a proactive approach and strategic foresight. By implementing these ten strategies—ranging from diversifying suppliers to investing in technology and fostering collaboration—companies in the steel and metals industry can fortify their supply chains against disruptions. Embracing resilience as a core principle enables businesses not only to withstand challenges but also to emerge stronger and more adaptable in the face of uncertainty.